- Hello Customer - Log in or Register!

The spherical roller bearing is the “work horse” of the industry. This bearing type primarily supports radial loads. It has two rows of barrel-shaped rollers, which conform closely to the raceways. This conformity, along with the size and number of rollers, gives the spherical roller bearing its heavy-duty load carrying capacity.

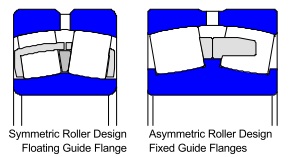

There are generally two basic designs for spherical roller bearings. A symmetric roller design, that uses a floating center guide flange that allows longer rollers to be used, which directly increases the radial load capacity of the bearing. The asymmetric roller design has fixed guide flanges on the inner ring. This design allows for greater thrust capacity and provides a more true rolling motion and is used almost exclusively on larger bearings.

Spherical roller bearings are generally available with two different cage designs, stamped steel and machined bronze depending in the size of the bearing. Spherical roller bearings are almost always manufactured with a groove around the center of the outer ring with three holes leading to the inside of the bearing. These holes feed either oil or grease into the working surfaces of the bearing.

EX Series

The Largest Load Rating in the World

50~100%* greater basic rating life under an equal loading condition

(* : compared with NACHI conventional design)

Wide Operating Temperature Range

EX series bearings are subjected to a newly developed heat stabilization and can be used at 200oC operating temperature with minimal dimensional changes and no life reduction.

| Product Model | Inside Diameter | Outside Diameter | Thickness |

| 7215C NTN | 75 | 130 | 25 |

| 7015C NTN | 75 | 115 | 20 |