- Hello Customer - Log in or Register!

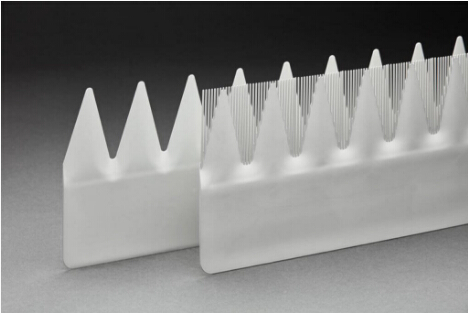

Silent operation of turbines is crucial for the success of many onshore wind projects. Siemens has therefore conducted extensive R&D over the last years to further reduce the noise of its wind turbines. An important breakthrough has now been achieved with the launch of a new generation of Siemens’ so-called DinoTail, an aerodynamic blade add-on. The trailing edge fringe of an owl’s wing provided the inspiration for this noise-reducing component.

| Product Model | Inside Diameter | Outside Diameter | Thickness |

| 603-ZZ bearing | 3 | 9 | 5 |

| 603-ZZC3 bearing | 3 | 9 | 5 |