- Hello Customer - Log in or Register!

Bearings in agricultural machinery: tough operating conditions are part of everyday life

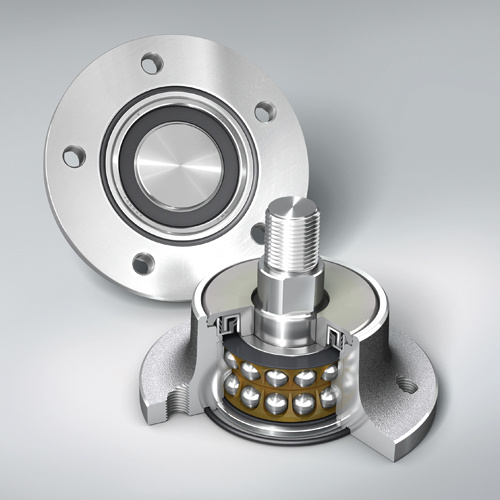

Bearings in agricultural machinery are often exposed to extreme operating conditions. That is why special series bearings designed from scratch for specific requirements are used in many cases. One example is the Agri Disc Hubs from NSK.

From a bearing manufacturer’s point of view, agricultural machinery technology is one of the most challenging fields of application. The requirements that bearings must meet can be clearly illustrated by taking disc harrows as an example. With this attachment, the farmer loosens the soil, breaks it up into small pieces and thus prepares it for sowing. The individual moving discs are set at a slight angle and each disc is mounted on a separate arm attached to the harrow’s frame.

Adverse operating conditions for bearings

When the harrow is used in normal operation, high axial and radial loads are applied to bearings. Furthermore, the bearings are subject to high shock loads if, for example, the disc hits a stone at a travel speed of 15 km/h or higher.

The influence of operating environment, which, with regard to the bearing application, can be considered extreme is at least of equal significance. The discs and bearings are exposed to heavy contamination. Corrosive substances such as fertilisers and liquid manure can also attack the bearings. In addition, many farmers clean their equipment with high-pressure cleaners on a regular basis, thus stressing the bearings and, in particular, their seals.

Agri Disc Hubs: standard programme and many OEM variants

NSK’s Agri Disc Hubs are ideal for these operating conditions. These are double-row angular-contact ball bearings which accommodate high axial and radial forces and are designed as an integral unit with a flanged housing. Unlike the wheel bearings of motor vehicles, which have a similar design and which NSK, as one of the world’s largest manufacturers, produces in their millions, Agri Disc Hubs are preloaded and free of play.

NSK offers these bearing units as standard products for disc diameters up to 800 mm; the current trend is clearly towards larger discs. The standard Agri Disc Hubs programme is mainly used by smaller, specialised manufacturers of agricultural machines and attachments, whereas the large manufacturers prefer customer-specific variants.

60 years’ experience in a highly specialised market segment

NSK’s history explains why the company is a market leader for custom bearings. One NSK production facility – Neuweg Fertigung GmbH in Munderkingen, Germany – was originally a bearing factory belonging to an agricultural machinery manufacturer. In 1990, NSK took over the factory, which was established in 1954. It not only has the necessary manufacturing capacity, but also has the means to design customer-specific bearings in a short space of time and bring them to series production readiness. This, of course, also includes the production of prototypes.

Highest demands on the seal

The seal is a central design element of the Agri Disc Hub. For this application a specially designed cassette seal system is used. This prevents clay, dust, plant residue and manure from entering the bearing. In addition, a steel disc protects the seal and the bearing against impact damage caused by stones. On the disc side an O-ring stops dirt and moisture penetrating the bearing.

Extensive field testing has proven that this sealing design is highly effective even under extreme operating conditions. It ensures a long bearing life even if the equipment is regularly cleaned with a high-pressure cleaner or a steam jet. During a 200-hour water jet test no water entered the bearing via the cassette seal.

Sturdy housing

The housings of the disc harrow bearing units are made of cast steel. They are extremely rugged and exhibit a very high level of mechanical stability. Another design characteristic is the ease of maintenance. The customer and the end-user expect this, as farmers may have to replace the bearings on their own. The design of the ready-to-install housing/bearing unit contributes significantly to this.

NSK designs the mounting of the Agri Disc Hub on the disc harrow’s support arms according to the customer’s wishes. Generally, different flange patterns are used, e.g. with four or five holes.

Lifelong lubrication provides benefits

Agri Disc Hubs are always lubricated for life. This has the advantage for the end-user that the units don’t have to be relubricated. This is a cost advantage, it saves time and the encapsulated design helps prevent grease escaping from the bearing and contaminating agricultural land.

Standard and custom bearings ‘made in Germany’

A modular system allows NSK to adapt the Agri Disc Hubs to meet customer-specific requirements with comparatively little effort. For example, a number of flange and shaft versions are available, which can be combined with the bearing units.

Moreover, a wide range of customer-specific bearings have been created at NSK Neuweg in close cooperation with the agricultural machinery manufacturers, which have been adapted to best meet the special requirements for agricultural technology. These include different types of pallet wheels, four-point contact bearings and double-row angular-contact ball bearings. New sealing concepts have also been developed in Munderkingen to cope with the unfavourable operating conditions found in agricultural applications.

Besides these customer-specific bearings, NSK also designs and manufactures standard bearing series worldwide for use in agricultural machinery. One example is inserts with square bores, which are used among other things to support the rotating wheels on attachments. These Self-Lube® bearings with lifelong lubrication can be simply pushed onto the shaft.

| Product Model | Inside Diameter | Outside Diameter | Thickness |

| NACV24X NTN | 11.11 | 38 | 24 |

| NACV22X NTN | 9.5 | 35 | 21 |