- Hello Customer - Log in or Register!

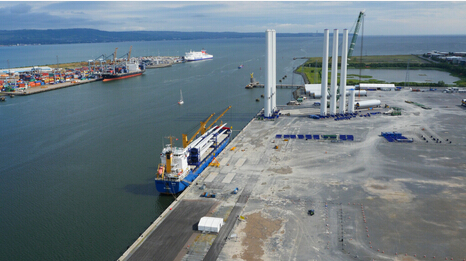

The offshore turbine blades that were designed, tested, and manufactured on the Isle of Wight have officially arrived at MHI Vestas’ pre-assembly facility in Belfast. There are ready for installation at DONG Energy’s Burbo Bank Extension project.

The first six 80-meter long blades for the 258-MW Burbo Bank Extension project have arrived at the MHI Vestas Offshore Wind pre-assembly facility in Belfast, Northern Ireland.

Offshore installation at Burbo Bank Extension, located 7km off the UK's west coast, is expected to begin over the summer and is due online in early 2017.

The first 80-m long turbine blades have arrived on site and installation at the offshore Burbo Bank Extension project, located 7 km off the UK’s west coast, is expected to begin this summer. The project is expected to be online in early 2017.

“It’s a significant milestone for the industry to see the world’s largest blades in serial production arriving in Belfast ready for installation. This marks the first time locally manufactured major components for offshore wind turbines are being used in the UK,” said CEO Jens Tommerup.

The blades for the V164-8.0 MW turbines – which were designed, tested and manufactured at the MHI Vestas’ blade factory – will be the first locally built blades to be installed at a UK offshore wind-power plant. The MHI Vestas factory on the Isle of Wight is where the unique skills and processes were developed that are necessary to produce blades on a large scale.

“Through investment and collaboration with our partners in the Solent region, we have created jobs, increased training opportunities and stimulated growth throughout the entire supply chain,” added Tommerup. “We believe that our efforts reflect the stimulation and growth that the UK has targeted with the continued investment in offshore wind power.”

UK Energy Secretary Greg Clark also commented on the project: “By building a strong, competitive UK supply chain we are creating jobs, attracting investment, and providing the certainty and confidence businesses need. We are committed to our world-leading offshore wind industry and now we have the first ever offshore wind turbine blades built in the UK by MHI Vestas.”

| Product Model | Inside Diameter | Outside Diameter | Thickness |

| 23034B NTN | 170 | 260 | 67 |

| 22334BK NTN | 170 | 360 | 120 |